Introduction

Thank you for reading this post, don't forget to subscribe!In a bold and unprecedented move, authorities in Kenya have announced plans to introduce an industrial-scale chapati-making machine capable of producing one million chapatis per day. This initiative aims to support a large-scale feeding program, primarily targeting school children in urban areas. While the idea has sparked excitement, it has also raised numerous questions about feasibility, logistics, and the practicality of such an operation.

This blog explores the details of this ambitious project, potential challenges, and what it could mean for food security and mass meal production.

The Vision Behind the Project

The concept of a machine capable of making one million chapatis a day stems from the need to enhance large-scale feeding programs, particularly in schools. With rising food insecurity, particularly in urban areas, authorities are seeking innovative ways to ensure that children receive nutritious meals. Chapati, a staple food in Kenya, is not only popular but also provides essential carbohydrates and energy for students.

Currently, most chapati production in schools and large institutions is done manually, requiring significant labor and time. The proposed machine is expected to automate the process, increasing efficiency and reducing the burden on human labor.

Understanding Large-Scale Chapati Production

While the idea of mass-producing chapatis with an automated system sounds revolutionary, it is not entirely new. Industrial chapati-making machines have existed for years, primarily used by large-scale catering services, military institutions, and commercial food manufacturers.

Typically, such machines involve:

- Dough Preparation – Ingredients are mixed automatically to ensure consistency in quality.

- Dough Rolling and Cutting – The machine rolls out the dough and cuts it into uniform shapes.

- Cooking Process – The chapatis pass through heated conveyor belts that cook them evenly on both sides.

- Cooling and Packaging – Cooked chapatis are cooled and packaged for distribution.

However, scaling up to a production capacity of one million chapatis daily presents a massive logistical challenge that few, if any, machines globally have achieved.

The Feasibility of the One Million Chapati Goal

Producing one million chapatis a day would require:

Flour Supply: Approximately 40,000 packets (2 kg each) of wheat flour daily.

Cooking Oil: Roughly 20,000 liters per day.

Water: Large amounts for mixing dough and cleaning equipment.

Fuel or Electricity: A significant energy supply to power the machine non-stop.

Storage and Transportation: Efficient logistics to distribute freshly made chapatis before they go stale.

Given these requirements, experts have raised concerns about whether the necessary infrastructure is in place to support such a large-scale operation.

Potential Challenges

- High Operational Costs

The cost of raw materials, labor, maintenance, and logistics for such a machine would be enormous. While automation reduces labor costs, expenses related to power consumption and ingredient procurement remain significant. - Quality Control

Large-scale food production often compromises quality. Ensuring that chapatis remain soft, fresh, and meet nutritional standards will require careful monitoring. - Food Distribution Logistics

Even if the machine produces one million chapatis daily, effective distribution remains a challenge. Without a well-coordinated system, food wastage could become a major issue. - Machine Maintenance and Longevity

A machine operating at such a high capacity would require regular maintenance. Any breakdowns could disrupt the supply chain, leading to inconsistencies in meal provision. - Environmental Impact

With large-scale wheat and oil consumption, questions arise about the environmental sustainability of this project. Waste management, water use, and energy consumption must be considered.

Public Reaction

The announcement of this project has sparked widespread discussions. Some see it as a game-changer in addressing food insecurity, while others remain skeptical about its feasibility.

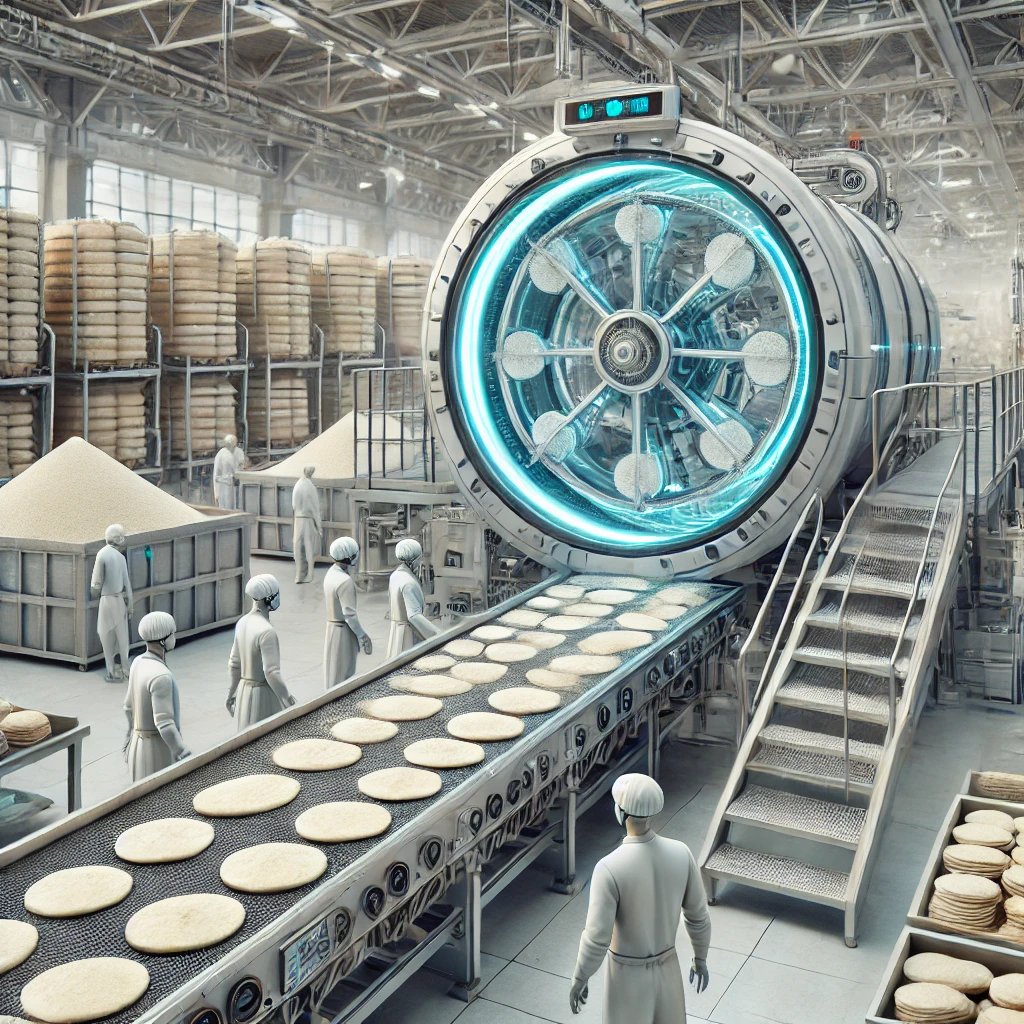

Many have taken to social media to express their opinions, with some questioning whether the project is realistic or merely political rhetoric. Others have humorously speculated about what such a machine would look like, leading to the creation of AI-generated images and memes.

Alternatives to Large-Scale Automation

While automation presents efficiency benefits, there are other ways to improve large-scale chapati production without relying entirely on a machine of such magnitude. Some potential solutions include:

- Community-Based Kitchens – Establishing decentralized community kitchens where trained personnel can prepare food at a manageable scale.

- Semi-Automated Machines – Using multiple smaller chapati-making machines instead of a single large one to ensure flexibility and minimize risks.

- Improved Food Programs – Investing in sustainable agriculture to lower food costs and improve meal programs at the grassroots level.

What’s Next?

As discussions continue, all eyes are on whether this ambitious project will materialize. If successful, it could revolutionize school feeding programs and set a precedent for mass food production in Africa. However, if the logistical challenges prove too great, it could serve as a cautionary tale about the complexities of large-scale food automation.

For now, the one-million-chapati machine remains a topic of debate, curiosity, and speculation. Whether it becomes a reality or remains a vision will depend on the planning, investment, and execution in the coming months.